The Art of Precision: Embracing Custom Plastic Injection Molding

Understanding Plastic Injection Molding

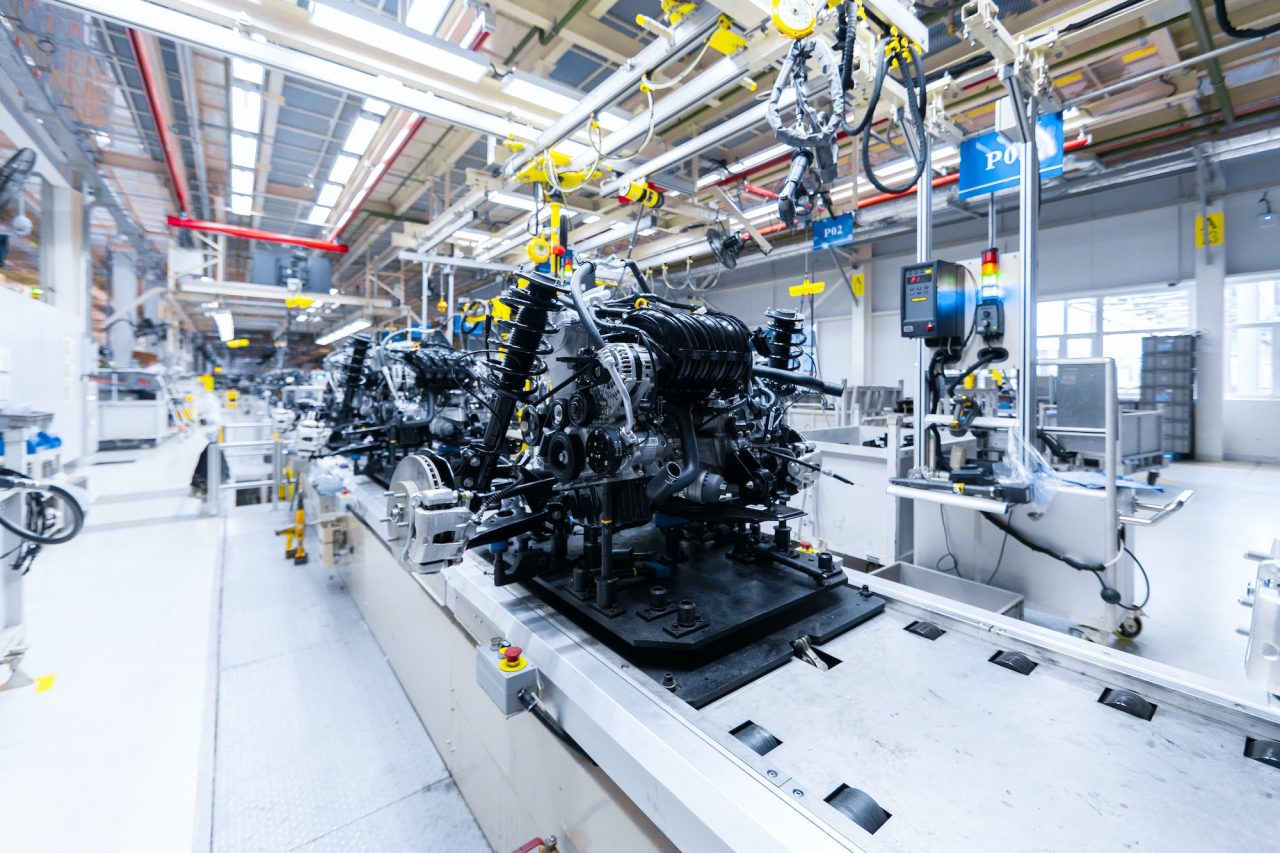

Plastic injection molding is a marvel of modern manufacturing, combining creativity with precision. It is a process where molten plastic is injected into a mold to create intricate parts and components. This service has revolutionized industries, allowing for the production of complex designs with high efficiency and minimal waste. Think of the sleek consumer electronics, automotive components, and even toys that surround our daily lives; most likely, they have been crafted through this innovative method. As markets expand and technology evolves, businesses can significantly benefit from utilizing a Plastic injection molding service that not only meets their demands but exceeds their expectations.

The Magic of Customization

When it comes to tailoring products to meet specific needs, custom Plastic injection molding takes center stage. This technique allows for the creation of unique designs that cater to individual client specifications. For instance, a company might need a specialized enclosure for a new gadget, ensuring it not only protects the internals but looks aesthetically pleasing as well. With a reliable partner providing custom Plastic injection molding, businesses can bring their visions to life, creating products that set them apart in a competitive market. Each piece produced is a blend of functionality and artistry, promising both quality and versatility in the final output.

Real-World Applications of Custom Plastic Injection Molding

Custom plastic injection molding is not just about functionality; it’s about redefining what’s possible in manufacturing. Industries ranging from medical devices to automotive components leverage this technology to create tailored solutions that resonate with their needs. For instance, a medical device manufacturer might require specific handle grips that accommodate various user dexterities; here, custom injection molding provides the chance to create ergonomically designed parts that enhance user experience. Further integrating this service into production lines results in reduced costs and improved time-to-market, allowing businesses to respond swiftly to changing consumer demands. For these reasons, embracing custom Plastic injection molding is a game-changer for any forward-thinking company.

Why APT-Mold Stands Out

With the rise of competitive offerings in the plastic manufacturing space, APT-Mold emerges as a leading choice. Boasting extensive industry knowledge and a commitment to quality, APT-Mold specializes in delivering tailored plastic injection solutions that not only meet but also anticipate client needs. They possess the resources and technology to handle large-scale projects while maintaining the craftsmanship that smaller operations often overlook. This versatile approach positions APT-Mold as a preferred partner for various industries. When it comes to achieving unparalleled quality and efficiency, partnering with APT-Mold guarantees that you access the best in custom plastic injection molding, propelling your business forward.

Leave a Comment